We test our products by a technical and trained testing team, to ensure the quality of the products. Process testing is performed during the production of the product, to work out errors in productivity. We are very strict on visual as well as technical testing. We use calibrated instruments to maintain test quality. Calibration of the equipment is being done annually, and slip is being pasted on the equipment.

- Relay functional testing

- Relay setting range testing

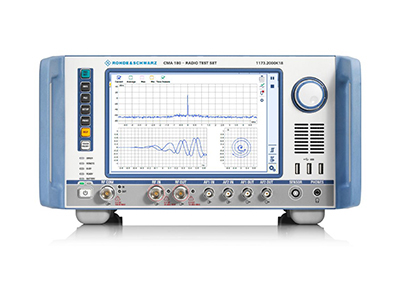

- Radio testing

- RF signal testing

- RF parameter measurement of various types.

- Measurement of voltage waves through an oscilloscope.

- Measurement of frequency and time of an oscillating signal.

- High Voltage testing.

- Insulation resistance testing.

- mV drop testing.

- Temperature rise testing.

- Transformer testing.

- AC & DC testing power supply setup.

- Ripple testing.

- Measurement of resistances.

- Electrical input testing.

- Fan speed testing.

- Noise level measurement testing.

- Air delivery for the fan.

- Fatigue testing.

- Heating testing on the permanent magnet.

- Gauss testing for fan magnet.

- Dark room facility for LED lux measurement.

- Endurance testing.

- Spring testing.

- Tensile testing.

- Operational/Functional Testing.

- Measurement of the weight.

- Mating cycle testing.

- No load voltage testing.

- Load testing with resistive load.

- Efficiency testing.

- Stability testing.

- Performance testing.

- Software burn-in testing for the emergency lighting system.