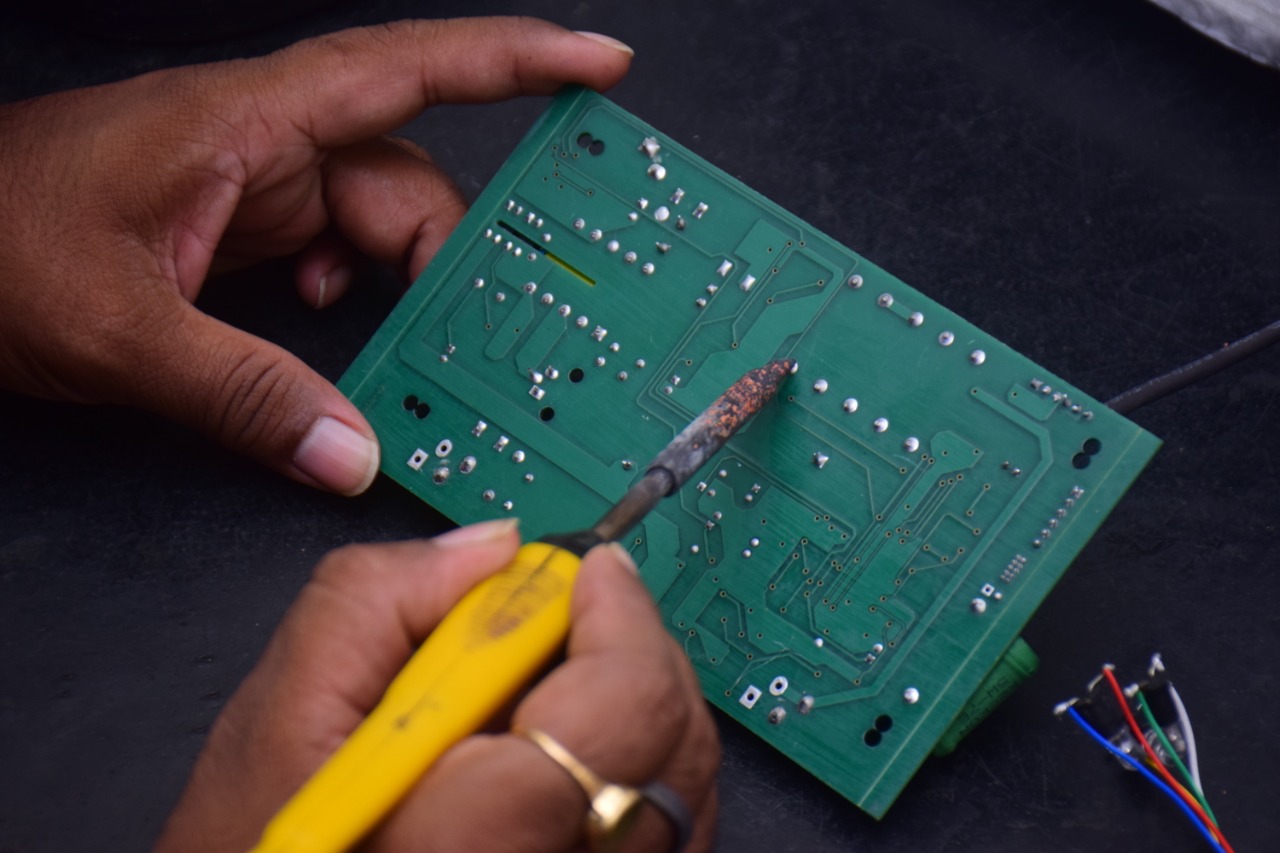

PCB testing Process

- PCB Testing begins with understanding that the PCB is the foundation for any printed circuit assembly.

- The circuit board is a top quality product that should not cause your end product to cost you money due to failures and recalls.

- So, for the testing process we have our own in-house PCB testing tools like AC/DC Power supply, Digital multimeter, clamp meter, IR meter, LUX meter, solder & De-solder station, and Debugger tool for programme verification testing & programming.

- It also includes Visual Inspection of track shorting & dry soldering to strictly check the damage of any PCB components.

- Our PCB testing process also includes the programming of PCB power circuits at specified voltage and current for its proper functional testing and quality check at the same time.